MMPA is committed to cooperative social responsibility and sustainable business practices throughout our entire supply chain. At the farm level, MMPA members are also on a sustainability journey. We’re checking in with a handful of member farmers leading the charge with this sustainability spotlight series.

Frank Burkett, a fifth-generation dairy farmer has sustainability at the core of his farming philosophy. “When I consider sustainability, I ask myself, ‘Could what we’re doing on a day-to-day basis today be repeated for perpetuity?’” Burkett said. It’s this philosophy that drives his decision making on Clardale Farms in Canal Fulton, Ohio.

“When we look at sustainability on our farm and what we’re most proud of, it’s definitely the fact that we farm in a very developed area amongst a lot of people and we try to be as open as possible, giving tours and telling the story of agriculture, sharing what we’re doing here.”

Burkett is a firm believer in agriculture’s sustainability story and along with sharing it with neighbors and those in his community, he recommends all farms invite local regulatory agencies to visit and tour farm operations. Building relationships and instilling trust in farming is critical to solving the larger sustainability issues at play.

“As we look to the world’s growing global population and analyze the fact that the United States dairy industry continues to expand exports, there is an opportunity for American dairy farmers to lead the sustainability dialogue within the dairy industry on a global scale,” Burkett said. “I am fortunate to know dairymen across the United States and I have a high degree of confidence that they’ll continue to innovate, and they’ll continue to actually show our global competitors how it should be done.”

His passion and confidence in dairy’s sustainability journey, recognizing that “agriculture is the beacon of sustainability,” comes with witnessing improvements through the decades.

“When you look at farming and what we’ve accomplished, the efficiencies that have been gained in agriculture over the decades, it’s impressive,” Burkett said. “It takes a lot fewer cows to produce safe dairy products for consumers today than it did 10 years ago, 20 years ago, 30 years ago. It’s only possible because we continue to adopt and learn and put new technologies into practice.”

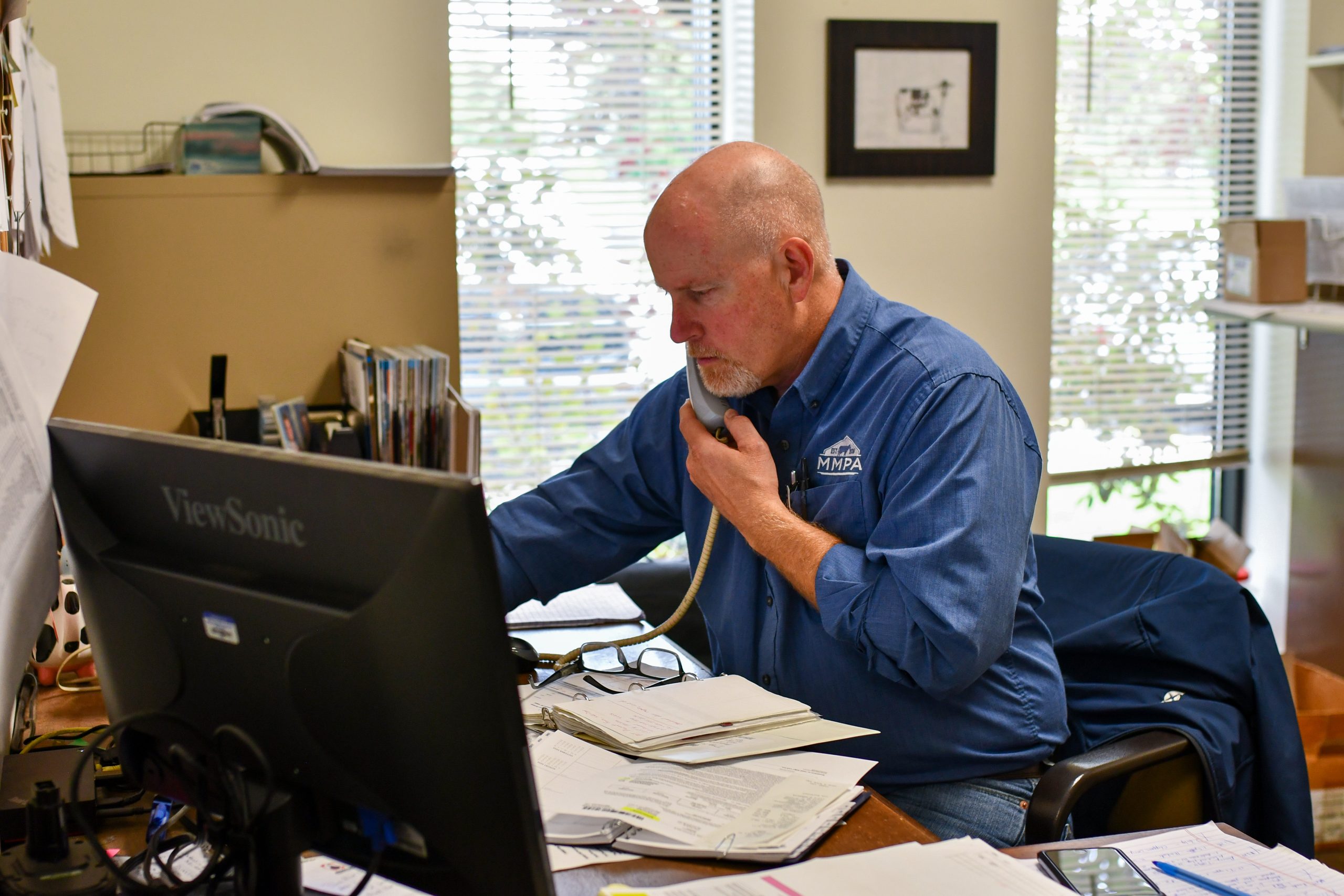

On Clardale Farms, these technologies start in the parlor where cow health is at the forefront of the data they collect. Using daily milk weights and cow activity monitors, Burkett and his team use the data to ensure the cows are healthy, happy and cared for.

“We focus on putting healthy animals into great facilities and really getting out of their way,” Burkett said. “We let them do what they do best and then surround them with an incredible team of people.”

The team of 13 full-time staff at Clardale Farms take animal wellbeing and environmental sustainability seriously and are critical to driving the future of the farm forward, one sustainable business decision at a time.

“I think there’s an educational component of sustainability. Are we learning from what we’re doing and making adjustments from there?” Burkett said. “We have technology and innovation coming at us continually, and if we’re not adapting and changing to meet that, then I don’t know if we’re going to be sustainable one year from now.”

Burkett humbly recognizes though that working with nature and making sustainable business decisions isn’t always as crystal clear and simple as it seems it should be, so he relies on peers to help guarantee success in the many innovations and technologies he encounters every day.

“I don’t have the ability to make the right decision every time,” Burkett recognizes. “Most of us hope we make more right decisions than wrong decisions, but I guarantee you, most of us, if we’re honest, we’ve made some bad ones. The more that we can share those bad decisions with others, we can hopefully try to accomplish the same sustainable outcomes just in a different way.”

But to achieve those sustainable outcomes, Burkett knows that profitability is critical to be able to invest in sustainable practices, technologies and innovations.

“Profitability isn’t a dirty word, it’s something that needs to happen for sustainability to be there, for the communities that thrive around us,” Burkett said. “The dairy farms that exist today, across the country are vital to their communities. The jobs that they enable have a huge impact and as family-owned businesses, we care about the community and where we are at. We live here too.”

Cow Activity Monitors: Cow activity monitors measure cow activity or movement. The computer takes this information and compares it to previously collected data to determine when a cow’s activity is increasing or decreasing. In addition to activity, many of these systems also monitor cow temperature, eating time and cow position (standing vs. lying). Cow activity and these other measurements are often combined to provide an overall indication of cow health.

SOURCE: Pennsylvania State University Extension

FARM

Clardale Farm

Canal Fulton, Ohio

HERD

699 milking

LAND

1,900 acres of corn, alfalfa and soybeans

VERIFICATIONS

MMPA Sustainability Survey, Nutrient Management Plan, Farmers Assuring

Responsible Management Animal Care, Farmers Assuring Responsible

Management Environmental Stewardship

This article was originally published in the May/June 2023 issue of the Milk Messenger. Subscribe »

By Doug Chapin, MMPA Board Chairman

By Doug Chapin, MMPA Board Chairman

By Tom Downey, MMPA Chief Financial Officer

By Tom Downey, MMPA Chief Financial Officer

Cyberattacks continue to appear in headlines every week across the world. From hospitals to retail giants, there aren’t many organizations or industries shielded from the effects of bad digital actors with criminal intent. MMPA member, Frank Burkett, recognizes the threat it plays to his farm and the agriculture industry as a whole.

Cyberattacks continue to appear in headlines every week across the world. From hospitals to retail giants, there aren’t many organizations or industries shielded from the effects of bad digital actors with criminal intent. MMPA member, Frank Burkett, recognizes the threat it plays to his farm and the agriculture industry as a whole.

By Joe Diglio, MMPA President & CEO

By Joe Diglio, MMPA President & CEO

A Lifetime Career

A Lifetime Career

A Humble Type of Extraordinary Service

A Humble Type of Extraordinary Service