Since just a few months ago, the entire world has flipped on its end. What seemed impossible the day before became the reality of the next day. The entire world slowed down, people stayed home and society ground to a halt. As the roads became less busy and the world quieted, those in the agriculture industry continued.

For the first time in a long time, consumers were searching for how their food was made after the grocery stores’ shelves that were always stocked became empty. Along with the panic, grew an overwhelming sense of generosity for the caretakers of our land and livestock, and for the people continuing to work as the world stood still.

In the Great Lakes region, March was the early days for the growing COVID-19 pandemic and as social interactions decreased and companies shuttered their buildings, everyone collectively began to feel the economic pressure a world at standstill was causing, the dairy industry included.

The situation at hand required that overnight, the dairy supply chain equip themselves to service unprecedented demand from consumers for gallons of milk in the dairy case. Processors bottled as much milk as fast as they could, but the supply chain is complex. After we successfully serviced retail customers, again, what felt like overnight, the demand for dairy was gone. Consumers were satisfied with the milk they had, and places of food service remained closed.

The rapid changing environment broke the dairy supply chain, and with a health crisis on top of it all, it pressured the minds and bodies of everyone declared essential. With the tides turned, the dairy industry rose to the challenge to meet the unified, unwavering goal of the entire supply chain.

We will adapt. We will overcome. We will keep producing dairy.

Dairy Never Stops

For farmers on the frontlines, that goal is an everyday reality. “Dairy farmers have planting to do, manure to haul, fields to get worked up,” Ben Chapin, MMPA field services manager, said. “Regardless of COVID-19, cows need to be milked, they have to push through.”

To help prepare the dairy industry for the worse case scenarios to come, the National Milk Producers Federation (NMPF) got to work preparing and releasing numerous resources to help dairy farmers prepare for the challenges at hand.

“As the magnitude of what was happening came into focus, we identified some immediate needs, which at that time were: what do farmers need to know about coronavirus and how it’s transmitted, and how can we prevent farmers and their workforce from getting infected,” Theresa Sweeney, NMPF communications manager, said.

As a member of NMPF, MMPA shared their resources as they were released with members in weekly email blasts, but despite all the help in preparing farms for a health crisis, at times, the impacts of COVID-19 still seem insurmountable to many.

“You come to the beginning of the year and you start getting excited about the promising looking prices and then this just took the whole sail right away. It even took the pole that the sail is on right off the boat,” Aaron Gasper, MMPA member from Lowell, Michigan, said. “You try to stay excited, but we’re back down to crunch mode. We’re still in crunch mode.”

The challenges caused by this crisis are difficult to prepare for. Nobody wants to think of what happens when they get sick and nobody wants to talk about the emotions these decisions cause.

“What if COVID-19 goes through my crew, or myself and the crew, all the sudden? Who’s milking tonight? Who’s feeding tomorrow? Who’s feeding calves? Are we going down to 2X?” Gasper asked. “If something were to happen what would we do? I really don’t know.”

Along with trying to prepare for the unknowns on his farm, Lew-Max Dairy, and handle the responsibilities of being a director-at-large of the MMPA board, Gasper was tasked with trying to find different sources of feed, like the distiller grains he uses in his feed ration now that his local distillery is producing hand sanitizer instead of brewing. He also had to have his sawdust trucked in from further away due to the local furniture shop also being closed.

“The world today is different,” Gasper said. “Everything has slowed down and done via telephone and via conference call and via Zoom. It’s not shaking hands.”

There are a lot of reasons to worry these days, and for Gasper, his biggest concerns are, “my employees, my milkman and where my milk is going.” Despite it all, Gasper is prepared to manage through it because, “this is unexpected and extraordinary times need extraordinary people to conquer them.”

Along with the challenges Gasper is facing, he’s taking advantage of the low diesel and feed prices, locking them in now to reap the twisted benefits of crashing markets. He encourages his fellow dairymen to look for positives in the situation and take advantage of opportunities like that, because “while this isn’t our fault, it seems like we are going to get the brunt end of it again.”

Social Distancing Haul Over

Gasper’s worries about the milkman are founded in the reality of the high-risk occupation for a pandemic like COVID-19. Milk haulers travel from farm to farm to farm and then to processing plants, coming in contact with numerous highly touched surfaces.

“Haulers can’t pick milk up at the farm if they’re being exposed when they come to the plant,” Therese Tierney, MMPA director of supply chain, said. “There aren’t a lot of people out there who drive for dairy and they’re just as important as every single dairy farmer and processing plant employee. Precautions have to be taken at every level of the supply chain to ensure that we can continue to market milk for our producers.”

Josh Salisbury recognized the risk in his milk hauling operation. With the help of his wife, Heidi, a registered nurse, he was able to rise to the challenge and implement safety precautions for his drivers, his mechanics and his office staff. Their first move was to construct a highly ventilated shed outside of the main shop as a safer solution for his drivers to drop of paperwork and pickup supplies needed for their routes.

“One at a time, the drivers can go into the shed, get their paperwork, drop off their paperwork and grab sample bottles. We also provide supplements for their immune system there,” Heidi said. “In the shed, we also have masks, gloves, alcohol wipes and all sorts of other supplies so that they can continue meeting the needs of the farmers and be able to do their job effectively every day.”

Josh and Heidi require their drivers to wear masks while on the job, air their truck out 10 minutes before they begin to drive and wipe down high touch surfaces in their vehicle regularly with alcohol wipes. They also have given thought to business continuity in the event that COVID-19 impacts the health of their drivers.

“So far, we’ve been fortunate that we’ve been able to keep everyone healthy,” Josh said. “In a situation that we had a bunch of people test positive, we haven’t had to cross that bridge yet, but we’ve tried to plan ahead for that as much as possible with cross-training. I don’t think you can plan for everything, you just try to do the best you can and try to have as many things in place as you can.”

When on the farm, Josh and Heidi encourage farm workers to keep their distance from their drivers and to not enter the milk house if the driver is in there. Adjustments like these are challenging when the milkman is a welcome sight on the farm, especially in difficult times like these.

Josh believes that “communication is key” to keep the strength of the dairy supply chain and to adapt to the necessary changes. “If any of our producers were to have any problems on the farm, if they would communicate with us, we can work through it with them,” Josh said.

A State of Preparation

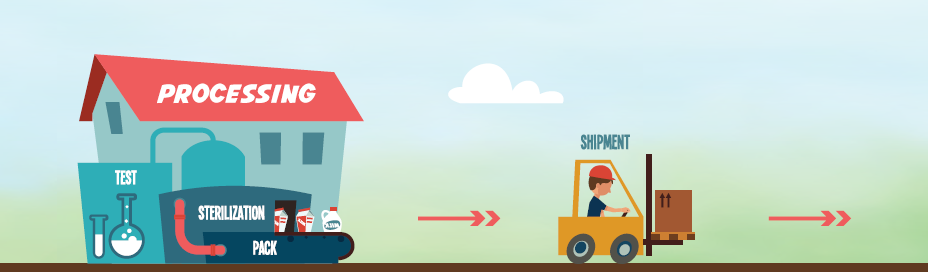

Along with good communication, preparation is key in the environment caused by COVID-19, yet at the same time, preparing for a pandemic seems incredibly extreme. Fortunately, due to their nature and the market they operate in, MMPA’s processing plants were ready to face the crisis at hand.

“Being an SQF certified organization, we understand microbial risks and always follow good management practices of handwashing, using hair nets and wearing clean uniforms,” Kaylan Kennel, director of MMPA manufacturing, said.

MMPA was also prepared for the need to be flexible when demand for raw milk surged over night and then rapidly declined a week later. MMPA plants have the ability to accommodate 50 percent of the cooperative’s raw milk. When needed, MMPA is able to fluctuate the amount of raw milk sent into their plants to meet customer demand for the product.

The ability to rapidly react to what customers are asking for is because of the assets MMPA’s members have invested into MMPA. Tierney believes that those investments are what is allowing MMPA to market the vast majority of member milk during these challenging times.

“When emergencies like this come up, Middlebury uses more milk by running more cheese vats on the barrel line. We put a UF line in Constantine so that it can process a lot more volume. Members invested in that large dryer at Ovid that is running at capacity right now and the churn investment has allowed MMPA to utilize more of the cream within our own plants,” Tierney said.

“We are putting our members’ assets to a maximum utilization right now and it’s because they made those investments that we have homes for their milk.”

MMPA is also at an advantage due to previous experiences with an over-supply of milk. “Although it was not a benefit at the time, when Michigan over produced four or five years ago, we learned a lot,” Tierney said. “We worked together to determine how to get the most benefit from our producers’ milk and it prepared us for another crisis like COVID-19.”

Today, the plants are implementing the lessons they learned from that to assist with the situation today, all while effectively managing the health portion of the crisis as it impacts plant employees. Bela Sandor, Middlebury Plant Manager, recognizes that “the greatest concern is the employees and their health.” Without labor on the frontlines, milk can’t be processed.

For that reason, MMPA plants have provided face masks for all employees and have made changes to daily workflow processes to encourage social distancing and increase sanitation of high touch surfaces. Kennel assures that “we are doing everything possible to make sure that we process our members’ milk while managing within this crisis. We have the members on our mind every day when we come to work at MMPA.”

The future is also a bright spot for Kennel because “during tough times, good organizations and good people have to stretch their abilities to meet the challenge and when we come out of this, we will come out a stronger organization.”

Going Back to Our Values

The tough challenges to come became a realization as stay at home orders were put in place across the nation and consumers rushed to the grocery store causing an unprecedented spike in demand for milk at the retail level. As MMPA’s customers turned to them saying that they needed more milk, “MMPA never said no,” Tierney explained. “We were able to fill the increased orders during the time of short-lived demand.”

“When our customers came to us, asking to increase their milk order and we were able to accomplish that, they were appreciative,” Tierney said. “We were also able to assist other customers where their suppliers could not. This excellence in service solidifies the reason customers work with MMPA.”

Meeting customers’ needs in times like these strengthen relationships. Throughout the entirety of this crisis, MMPA has banded together, from a distance, to communicate with customers, meet their needs and fill their orders.

“The whole team, the staff, the plants, the entire co-op did an excellent job, responding to when demand spiked in terms of moving milk where milk needed to be in that third week of March,” Jim Feeney, MMPA senior director of sales, said. “We didn’t miss a beat. It was a coordinated effort. And then, when the demand just kind of stopped, I say the same as well. The same coordinated effort across MMPA is happening. It’s much bigger than customers, it’s supply chain, operations, finance, communications, our members, everyone.”

Just as the rest of the dairy industry, MMPA was impacted by the loss of the food service outlets. Even orders for products that are used mostly outside the food service channel, like yogurt, are different in the new COVID-19 era.

“Our customers are metered in how they’re ordering,” Feeney said. “Ultimately, there is less than normal demand right now.”

The current situation has resulted in uncertainty and unpredictability surrounding consumer demand and what may lie ahead. Feeney said within the industry, there is “concern about producing too much too quickly, challenges within distribution and products reaching expiration dates before they get sold.”

The uncertainties of everything right now are impacting all areas of the supply chain, yet customers are turning to MMPA for the same reasons they always have. According to Feeney, they’re “looking to us for consistency, for reliability and for assurances that our products are going to be available as they need them.”

Tierney echoes the same, “First and foremost, we always have fresh, high-quality milk quickly. That’s a standard. We don’t compromise on that.”

In addition to servicing the needs of customers, MMPA has made several donations of milk, cheese and butter to food banks in Michigan and Indiana. MMPA’s donations helped support the surge in demand at local food banks during a time when milk was at surplus in many parts of the country.

As the supply chain works together in this broken state, know that we are united. Feeney says it best, “We are working on solutions to find a market for milk, all of us. There is a singular focus from everybody. It’s what is driving everyone. There is an unwavering common goal throughout the supply chain.”

This article was originally published in the May/June 2020 issue of the Milk Messenger. Subscribe »