Chocolate. It’s a moment of joy, a mood-booster, a celebration, a comforter. The tantalizing mix of cocoa, sugar and milk captivates people around the globe every day and fuels a $103 billion industry.

Behind one out of every four pieces of chocolate in the world is the Swiss-based Barry Callebaut Group, according to Kevin Ogorzalek, the chocolatier’s manager of sustainable sourcing.

“We are the heart and engine of the chocolate industry,” Kevin Ogorzalek said to MMPA members during a presentation at the Leaders’ Conference held November 22, 2019.

A global footprint

An MMPA customer, Barry Callebaut is a multinational corporation established through the merger of Belgian chocolate maker Callebaut and French chocolate producer Cacao Barry.

“We are a growing business. We are a global business,” Ogorzalek said, noting the company has over 175 years of chocolate heritage.

Today, the world’s leader in chocolate manufacturing and cocoa processing, Barry Callebaut operates 62 factories worldwide and employs over 12,000 people.

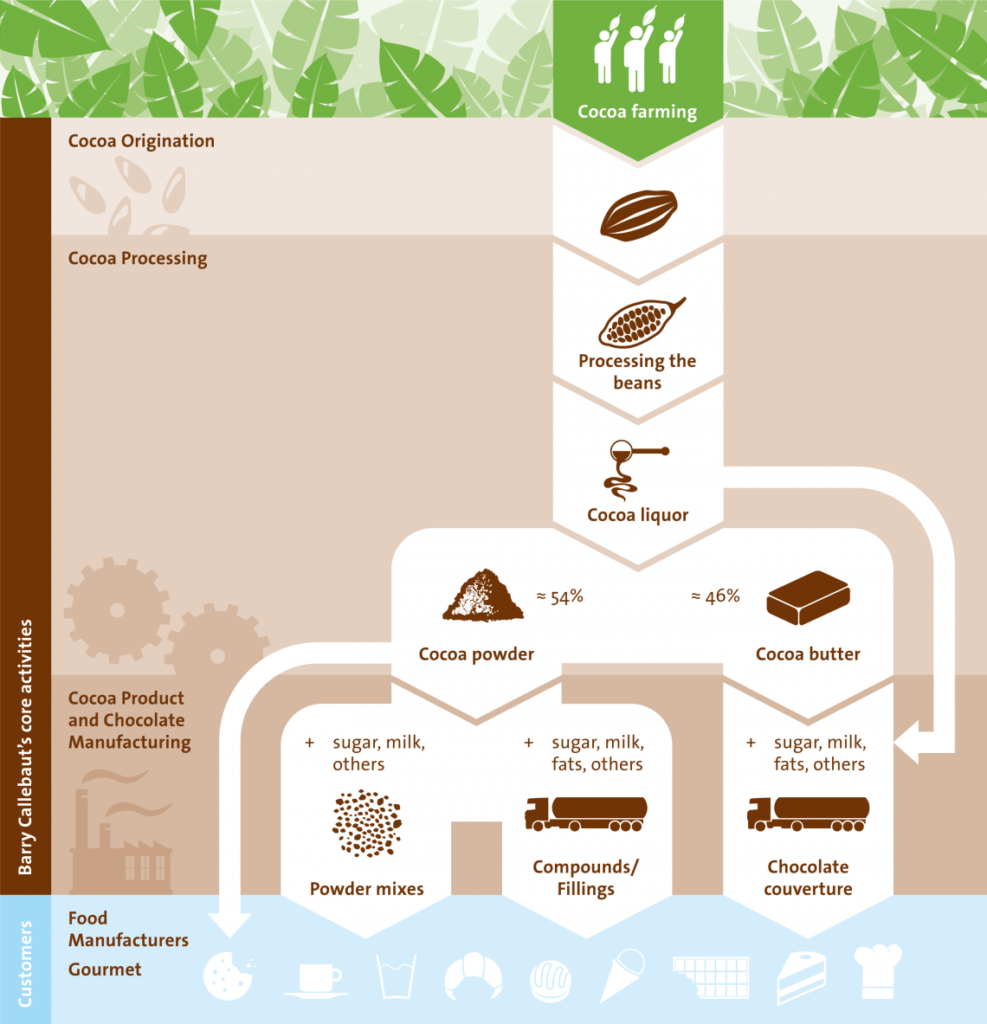

Chocolate has a complex and storied process that begins with the cocoa bean. Grown in hot rainy areas near the Equator, farmers harvest cocoa beans for Barry Callebaut, who then processes the beans into cocoa liquor. Like milk, cocoa is broken down into fat and protein in the form of cocoa butter and cocoa powder, says Kaitlin Nolan, Barry Callebaut dairy sourcing manager.

Depending on the end use, Barry Callebaut then adds sugar, milk, fats, nuts and other ingredients to the cocoa butter and powder to develop finished and semi-finished products. A business-to-business company, Barry Callebaut sells its products to food manufacturers and artisanal and professional users of chocolate, such as chocolatiers, pastry chefs, bakers, hotels, restaurants or caterers.

High quality dairy

While dairy is only one facet of the chocolate making process, Nolan says high quality dairy ensures theycan consistently produce high quality chocolate.

“Milk is very important because to make great milk chocolate you need to ensure you have that milky flavor. The taste and mouth feel that comes from the milk is very important,” she said.

All suppliers, MMPA included, go through an approval process with Barry Callebaut’s sensory department, who examines taste, smell and mouth feel of the products.

Barry Callebaut sources significant volumes of dairy in the Americas, according to Ogorzalek. Dairy ingredients used in chocolate include powder (skim, whole and buttermilk), whey products, butter fats, lactose, milk and whey proteins, and casein and caseinate.

Partnering for Forever Chocolate

With a global footprint and a wide range of sourced ingredients, behind each chocolate bar is a complex web of relationships and impact on the planet. With a goal of ensuring chocolate is around for future generations, Ogorzalek says Barry Callebaut is on a sustainable sourcing journey.

“We don’t see this as a top down approach, we see this as an opportunity to learn together to grow together,” he said.

Through their “Forever Chocolate” program, Barry Callebaut is partnering at every level of their supply chain to make “sustainable chocolate the norm by 2025.” Their targets include lifting 500,000 cocoa farmers out of poverty and producing their products with 100 percent sustainably sourced ingredients.

“Everything we do in our sustainable ingredients sourcing efforts focuses on verifiable economic, social and environmental continuous improvement,” Ogorzalek said. “We also do it in our own operations. I want to demonstrate that we at Barry Callebaut are walking the walk.”

Internally, Barry Callebaut is implementing renewable energy in their factories, reviewing their ocean fleet and land freight to reduce emissions, and investing in their cocoa and non-cocoa supply chains. One project reduced natural gas use at a manufacturing facility by bio digesting cocoa shells, which were previously discarded.

In addition to investments in their own operations, Barry Callebaut is working with all its ingredients—including sugar, vanilla, nuts and dairy—on sustainability. Acknowledging dairy farmers are stewards of their land, Ogorzalek says they hope to learn from farmers by partnering with suppliers like MMPA.

“Knowing that MMPA has 100 percent participation in the FARM animal care program is fantastic and something you should be extremely proud of,” Ogorzalek said. “You also have some of the highest quality milk in the country with low somatic cell count.”

In further partnership, Barry Callabaut recently sponsored a handful of MMPA farms to participate in a pilot project with a feed additive, Agolin. Chipping away at Barry Callebaut’s goal of reducing greenhouse gas emissions, the blend of plant extracts is designed to optimize feed intake and digestion. Ogorzalek says results have been positive so far by reducing methane emissions and increasing farmers’ profitability.

“We are seeing a range of financial benefits for all farmers participating in the pilot,” he said. “We also see this as an opportunity to build trust as we go on the journey of sustainable sourcing together. We are learning what works, what doesn’t work and sharing costs in the process.”

Moving forward, Ogorzalek says Barry Callebaut is looking to expand with companies like MMPA who are willing to collaborate for long-term sustainability. “We want to ensure future generations will have chocolate,” he said.

Recognizing the contributions of MMPA members, Ogorzalek concluded with gratitude toward dairy farmers and the role they play in the chocolate making process. “Thank you for providing quality products for Barry Callebaut so that we can continue to grow together.”

This article was originally published in the January/February issue of the Milk Messenger. Subscribe »